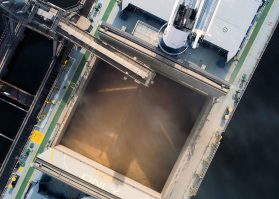

The Port of Gdańsk is ready for grain

Although grain handling had already increased significantly in all Polish seaports last year, which is directly related to the blockade of Ukrainian ports on the Black Sea, it was overshadowed in the first months by the gigantic volumes of coal handled at the ports. In recent months, however, more and more has been said and written about grain. Ports and operators already have their hands full and are preparing for further increases.

In 2022, the Port of Gdańsk handled around 2 million tonnes of grain, which was a record for the port. At the same time, this was 19 per cent more than the year before. The first half of 2023 brought another huge increase in agro handling.

‘Polish ports, including the Port of Gdańsk, the largest of them, were prepared to handle more grain. Although this was a considerable challenge, they rose to the occasion. This can be seen from the handling results for the first half of this year. In the six months through the Port of Gdańsk, the grain terminals exported around 1.4 million tonnes of grain, especially corn, an increase of 52 per cent compared to the same period last year. It can be compared with just over 1.9 million tonnes of grain handled by the Port of Gdańsk throughout the whole of 2022’, explains Marek Gróbarczyk, Deputy Minister of Infrastructure.

The port is preparing for an increase in grain shipments. As approximately 70 per cent of the grain transport to the port is done by lorries, it was necessary to increase the number of parking spaces – currently, there are 970. They shall allow unloading of the port arteries and access roads, as it is estimated that during the peak traffic period, up to 1,500 lorries with grain may enter the port. Four parking areas will be staffed by J.S. Hamilton grain sampling facilities. This is because, without proper testing, grain is not loaded onto the ship. Testing takes place 24 hours a day, regardless of the weather, which is made possible by the roofing of the sampling devices called Rakoraf. In July, J.S. Hamilton opened additional stands in the Port of Gdańsk. As a result, it is able to handle more than 700 vehicles per day. This has almost reduced the queues of waiting drivers.

The handling of grain is possible within the port area at several different quays, including Wiślane, Zbożowe, Oliwskie and Bytomskie. It is carried out by a total of six operators: GBT/Malteurop, Port of Gdańsk Eksploatacja, Speed, Siark-Port, Gdańskie Młyny and Magrol.

However, a significant increase in cargo handling capacity is a process spread over many years. According to the plans, the operators working in the Port of Gdańsk will develop their capacities over the next two years to such an extent that the port’s throughput will increase to around 5.8 million tonnes per year.

‘The current capacity of the Port of Gdańsk’s main grain terminals is 300,000 tonnes per month, and the storage capacity is 126,000 tonnes. The operators can handle 730 lorries and 80 goods wagons per day. But they are ready to increase their cargo handling capacity. They plan to erect permanent and tented warehouses, and want to make rail investments. They estimate that the erection of facilities for the storage of agricultural products will cost PLN 68 million. With such investments, the cargo handling capacity of the Port of Gdańsk’s grain terminals is set to increase to 485,000 tonnes per month (5.8 million tonnes per year). And the target storage capacity is to increase by 65,000 tonnes to 191,000 tonnes. Of course, the Port of Gdańsk Authority SA is also open to new investors planning large-scale agro handling’, explains Kamil Tarczewski, Vice-President of the Port of Gdańsk Authority SA.

Exporters invest

Viterra, one of the leading exporters of grain, also draws attention to the need for constant upgrading of port infrastructure for the sea route.

‘The capacity of Polish terminals keeps increasing, which allows us to achieve new records in the volume of exports from Poland. However, compared to modern terminals in Western Europe and in Baltic countries such as Lithuania and Latvia, there are still many areas where we can make improvements, such as upgrading infrastructure and loading processes’, says Grzegorz Sobczyński of Viterra Polska.

However, investments in infrastructure take time. Warehouses, railway sidings and, for example, cargo handling devices are required. In terms of the latter, the port company PG Eksploatacja is steadily developing its capabilities. Recently, the second of three new harbour cranes, a Liebherr LHM 550, began operating in the company’s colours. The first was delivered in winter, while the third is expected to arrive at the end of 2023. These versatile machines are equipped with grabbers for handling a wide range of goods, obviously including grain.

‘The new handling devices represent an increase in productivity and maintain long-term handling stability. Currently, the company also uses the recently acquired RIMO SL1400/M mobile shiploader for agro handling, which has significantly improved handling efficiency, but also stabilised our operational activities in the loading process. After the renovation of the Wiślane Quay, the conveyor belt will be used for the direct loading of goods from the warehouse, thus creating another ship loading station. The next step and challenge for the company will be to increase storage space for agro goods’, explains Szymon Mikołajczak, commercial director of PG Eksploatacja.

PG Eksploatacja’s current handling capacity is estimated at 150,000 tonnes per month.

‘The maximum handling capacity has been determined on the assumptions of homogeneous storage in warehouses and a full rotation of vessels with a loading capacity of more than 30,000 tonnes. At present, we notice that our warehouses receive agro goods from the previous and current harvests in various commodity groups and of different quality, which means that our storage and handling capacity is not fully utilised’, adds Szymon Mikołajczak.

Relieve the market

Everyone wants handling to take place as quickly as possible – this reduces traffic jams and lorry downtime and shorter quayside stops. The GBT terminal, one of the six grain terminals in the Port of Gdańsk, is currently able to unload up to 7,000 tonnes of grain per day from lorries and up to 1,800 tonnes from goods wagons. Going further, up to 10,000 tonnes of grain per day can be loaded onto a ship at the same terminal. However, these figures will soon be out of date. Rafał Różański, President of the Management Board of GBT, estimates that at the moment, the terminal is using 90 per cent of its handling capacity. The terminal is constantly working to increase its capacity.

‘The upgrade of the terminal is being carried out comprehensively with the purpose of improving and speeding up the cargo handling process at every stage’, says Rafał Różański.

According to President Różański, part of the project has already been completed. Three new tent halls have been erected, increasing the storage base by 17,000 tonnes. There is also an external parking area with a covered sampling and testing place for 54 lorries. More investments are underway. Among them are an additional line for unloading grain wagons and an additional track for rail shunting. Work is also underway for the purpose of increasing the ship loading speed to 600 tonnes per hour and reducing dust at the terminal. The company is also buying mobile devices for unloading grain wagons.

‘The bottleneck is reception logistics, proper scheduling of deliveries so as not to make vehicles and goods wagons wait a long time to be unloaded. In consultation with the port and the Hamilton control unit, we are working on a system of hourly notification, which should spread the burden of deliveries. The Port of Gdańsk Authority SA has been highly involved in supporting grain handling, acting as the initiator of many meetings and panels with the purpose of eliminating bottlenecks. In a short period of time, infrastructure has been put in place that strongly supports the terminals both logistically and IT-wise. This is confirmed by both the volumes exported at the port and the daily volumes delivered by rail and road’, adds the president of the GBT terminal.

The activities of the Port of Gdańsk Authority SA (PGA), are also positively evaluated by Szymon Mikołajczak from PG Eksploatacja. As he says, the PGA’s involvement in, for example, the construction of new parking areas has benefited both the operators and the city’s residents.

‘It has been, and will continue to be, crucial for operators and the PGA to deal with potential congestion caused by lorries bringing agro goods to the port. Causing congestion in the continuity of the supply of agro goods to the port causes the port operator to miss out on its operational capacity. Residents have felt the PGA’s investment in their daily lives through the absence of traffic jams, and PG Eksploatacja has increased its handling capacity by being able to spread agro goods deliveries out over a 24-hour period’, he explains.

Viterra Poland is also preparing for the season. ‘It is worth noting that in the 2022/23 season, half of the grain exported by sea was shipped to African countries, which confirms the high quality of Polish products and the trust we enjoy among international recipients. Nevertheless, due to the growing competitiveness of cereals from other regions, we are constantly looking for new markets for Polish agricultural products. One of them is, for example, the market of the United States, which has been uncommon for our activity so far. Every year we also invest in streamlining the entire process, from automatic sampling to the use of modern laboratory equipment, which significantly reduces the time Polish farmers have to spend waiting for their produce to be accepted. We take all possible measures for the purpose of relieving the market of grain surpluses and increasing export opportunities’, adds Grzegorz Sobczyński .